Fiber optic interconnect test solution

7/7/15 | Technical ArticleThe rapid development of information technology, the popularity of network-based technology advances, prompting data center construction continues toward large-scale, high-density, high transfer rate, pluralism, virtualization, intelligent, green direction. At the same time, for faster data transfer rates, smaller footprint, lower energy consumption needs, making the data center physical infrastructure as an important part of the cabling system more and more people's attention. Fiber and copper cabling system in the data center are two basic transmission medium, compared with copper systems, fiber-optic network with greater bandwidth, faster transfer rates, longer distances, more slender volume, and stronger anti-interference ability and so on. Therefore, although limited by the high price factor optical fiber, optical fiber can be completely replaced by copper, but the data center construction "Light of Copper" trend is inevitable.

Fiber optic cabling system data center applications to increase in proportion to provide more opportunities for the application and development of optoelectronic components. Fiber optic connectors are used in the optical system of the largest optical passive components, widely used in telecommunications, local area network (LAN), fiber to the home (FTTH), high-quality video transmission, fiber optic sensing, test instrumentation. Fiber optic connector components is carried out detachable connection between the optical fiber and optical fiber, which is the two end precision optical docking, so that the light energy emitted optical output can maximize the receiving fiber coupled to go. It is because of the use of connectors, enables the removable connection between optical channels as possible, so as to provide a fiber optic test entrance, facilitates the testing and maintenance of the optical system; and to provide a medium for network management, the optical system transit dispatching more flexible. Throughout its development, the development of optical fiber has two distinct phases: the first phase, in order to save space, the miniaturization of the optical fiber connector from the traditional FC, ST, SC development of LC, MTRJ, E2000; the second stage, not only in order to save space, but also to meet the requirements of multi-core use, fiber optic connector from the LC, MTRJ, E2000 to MU, MTP / MPO evolution, now a MPO / MTP multi-pin connector to meet the 2-core, 4-core, 8-core 12 cores, 24 cores, currently up to 72 core requirements.

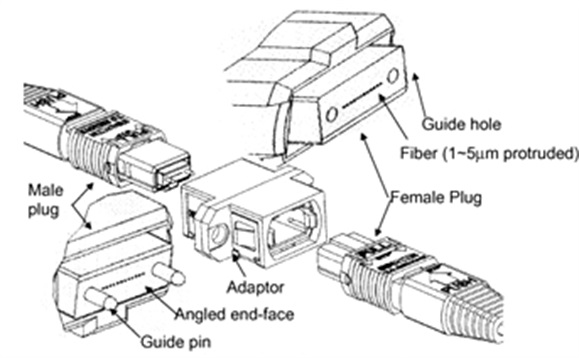

With after June 2010 with the IEEE 802.3ba new Ethernet 40G / 100G standard release, the future deployment of fiber optic backbone data center, MTP / MPO to MTP / MPO and using OM3 / OM4 fiber pre-connected programs become become 40G / 100G preferred link. MPO optical connector is a multi-core multi-channel plug connector, while the MTP MPO connector specific US conec company registered the brand. MPO connector is characterized by a standard rectangular ferrule diameter 6.4mm × 2.5mm, the use of both left and right end surface of the ferrule guide apertures having a diameter of 0.7mm and a guide pin for positioning. When docked, there is a ferrule mounted in the tail of the spring exerts an axial pressure on the ferrule until the connection head frame with adapter sleeve locking. Ferrule with a convex button on the side of the relative position of the joint is used as a connection between the restrictions, in order to determine the correct fiber mating sequence. The structure shown in Figure 1.

MPO / MTP pre-connected systems meet the needs of high-speed and high-capacity optical fiber communication system of high density and high efficiency interconnect cabling is the preferred data center cabling system solutions. First, MPO / MTP pre-connected systems can greatly reduce the use of data center space, to achieve its high density; secondly, the demand for high speed data transfer rate of high-density multi-core optical fiber to promote adoption; and finally, the use of high-density pre-connection system can significantly reduce on-site installation time, but also significantly reduce on-site installation performance impact probabilities and performance uncertainty.

However, with the MPO / MTP fiber optic connector is also brought new challenges for data center optical interconnection test. The traditional method is to use fiber optic test MPO fiber optic connector at one end with the other end of the fan opening is 12 single-channel fiber optic connectors, this single-channel fiber optic connectors can be connected to the existing optical power measurement device, so to the construction site will be able to provide the necessary test conditions. The implementation of this test method, if the field only one optical power measurement device, you need to keep the connection in order to meet the test needs 12 channels; and if you need a one-off for all 12 channels optical power measurement, you must respectively, in the optical fiber connector end 12-channel 12-channel connection of optical power measurement device. Obviously, this method is complicated to operate, poor stability test, a long test time and high cost. For this reason, some companies introduced MPO interfaces onboard light source and optical power meter. Using MPO connector having a light source and optical power meter, one-time set-up and decay benchmark 12 link tests automatically detect MPO optical performance and issue a report. MPO Test Connectors onboard handheld FMP-10 & FMS-10 MPO tester kit, shown in Figure 2. Jumpers can be directly without the use of fan-shaped test jumper with MPO connector insertion loss, and visually displays all test results. These innovative feature eliminates the complexity of testing MPO fiber optic cable, test time required is much less than the traditional single-source test. The package in a variety of environments to provide fast and reliable measurement, small size, light weight, durable, access network installation and maintenance necessary special tools.

Product features:

※ onboard MPO test fittings, automatic test all fiber MPO connectors within

※ simple, full-featured

※ MPO light output mode can be set

※ FMP-10 MPO optical power meter with multiple parameter setting

※ with data storage capabilities, USB interface can directly upload data

※ dual power saving design: NiMH rechargeable battery / AC adapter, auto-off function

※ handheld, compact and convenient, durable

In addition to the handheld test suite, there are more full-featured desktop MPO fiber optic patch cord test system --GJ800 multi-channel passive component test system, shown in Figure 3. Whether handheld or desktop tester, fiber optic cabling can be used to test data centers and MPO / MTP pre-connected system manufacturer's product testing.

Author: FiberOnSale.com

fiber, interconnect, tes, solution, data center, MPO

fiber, interconnect, tes, solution, data center, MPO